Do you have questions about our products?

Do you need our service?

Contact

Michael Huth

+49 - 6161 - 93 07 - 44

moc.m1769142522etsys1769142522-kz@h1769142522tuh.m1769142522

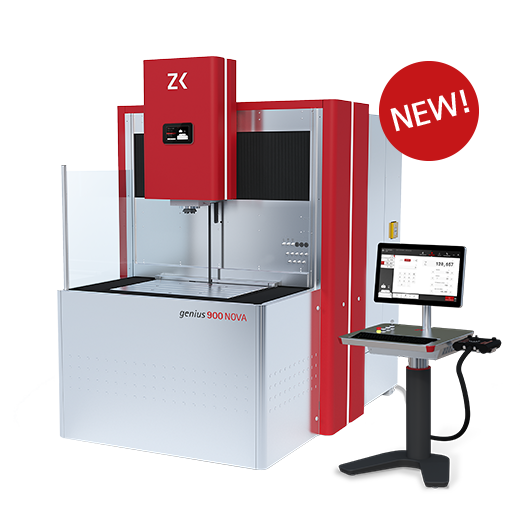

With the genius 900 NOVA, you can explore an entirely new eroding terrain. And that in every respect: No matter whether speed, accuracy / precision, stability or flexibility. The genius 900 NOVA can justifiably be referred to as the best of its class.

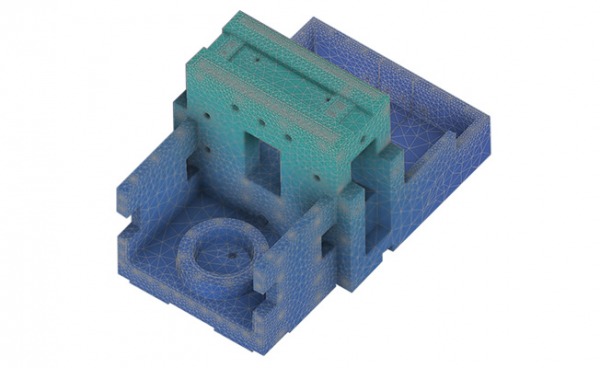

The compact substructure made of mineral casting ensures steady work results, even in case of temperature fluctuations in the environment.

Faster, more precise, genius 900 NOVA.

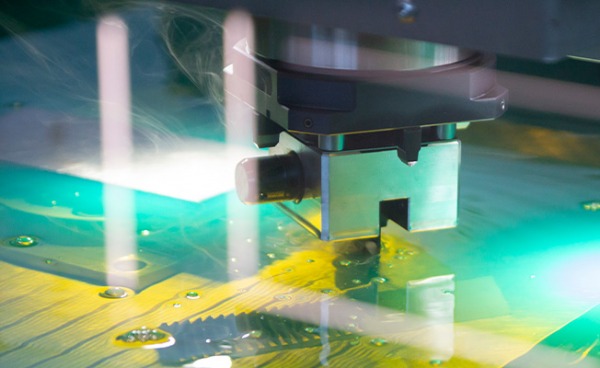

The fundamentally new developed machine leaves nothing to be desired: High speeds in all axes. At the same time, low-wear erosion with copper or graphite as well as steady process runtimes are ensured. The genius 900 NOVA impresses each user with stunning precision, speed and flexibility.

The features at a glance:

- Simultaneous 8 axes operation

- Manual eroding for teaching electric discharge machining via manual control with joystick function

- LCD display and Windows 10 touch monitor

- High vibration dampening due to mineral casting

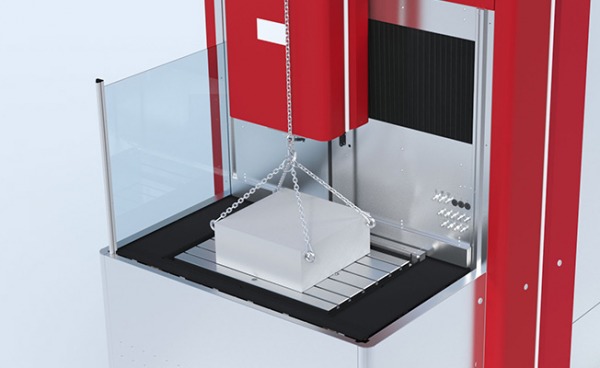

- Movable tank (without dielectric emptying)

- Acceleration 1G 10 m/sec²

- Highest erosion performance and precision for all material pairs

- Wear-free final dimension tuning

- Thermo-symmetric mineral cast construction

- Fully enclosed integrated measuring systems

- Integrated electro cabinet cooling (standard)

- Fully temperature-controlled machine frame (optional)

- LED status display (optional)

- Fully integrated workspace lighting (optional)

- Freely programmable flushing (optional)

- Automatic central lubrication (optional)

| Height | 2650 mm |

|---|---|

| Width | 1800 mm |

| Depth | 2750 mm |

| Total weight (w / o fluids) | ca. 7000 kg |

| Table: Length x width | 600 x 900 mm |

| Dielectric fluid above table | 450 mm |

| Dielectric filter | 1 central filter |

| Workpiece weight | 1000 kg |

| T-slots: number / width / distance | 6 slots / 10 mm / 83/100/100/100/83 mm |

| Distance: Table – sleeve w / o chuck max. / min. |

550 / 150 mm opt. 660 / 260 mm |

| Travel distance X – Y | 720 x 420 mm |

| Travel distance Z | 400 mm |

| Resolution X – Y – Z | 0,001 mm |

| Rapid travers rate X -Y | 20 m / min |

| Rapid travers rate Z | 20 m / min |

| Electrode weight | max. 100 kg |

| Dielectric fluid consumption | 560 litres |

| Number of adjustable feet | 3 pcs. + 2 columns |

| Weight per foot | ca. 2,9 t |

| Required cooling power | 4,5 kW |

| Floor load | ca. 1,65 N/mm2 |

| Space of base plate | 1x Ø 150 mm. 2x 150 x 150 mm |

| Flow rate (air) | 10l / min |

| Required air pressure | min. 6 bar |

Generator data:

| Control system generator | IPMtec (integr.) |

|---|---|

| Operating current | 52 A in total optional 100 A in total (+ 48 A) Booster 196 A in total (+ 96 A) |

| Suction capacity | 6 KVA / 400 V / 50 Hz |

| Handling | Stand alone operator panel with keypad, mouse and genius NOVA handheld terminal |

| Screen | 22“ Touchscreen |

| Screen | IPC Intel Windows 10 |

| Control system machine | own RISC-CPU with 1.2 GHz and 64 Bit |

| Gap monitoring | own RISC-CPU with 1.0 GHz and 64 Bit |

| Engine control | Digital controller for AC-servomotors |

| Interface | LAN-TCP/Internet protocol, USB, RS 232 |

Machine details

(air-water heat exchanger)

-

Control via touch screen

-

Fully integrated job manager possible

-

Direct import of CAM data for program creation (no manual programming necessary; optional)

The next dimension of machine control: Simple, clear, perfect.

New handheld terminal genius NOVA

- Ergonomically shaped

- Two approval buttons for left- and right-handers

- Large LCD display

- Digital handwheel for manual target positioning (optional in combination with geniustransfer)

- Connection cable of individual lenght (standard 8 m)

- Fully integrated 4 axes joystick control