Little wear, precise contours, very fine surfaces

n IT and medical technology, minuscule parts with perfectly smooth surfaces are used. The requirements for the EDM process are above all highest precision with fast processing and low wear. With the genius 602 Nano, Zimmer & Kreim has specialised in precise and low-wear machining with extremely small electrodes in the micro-range.

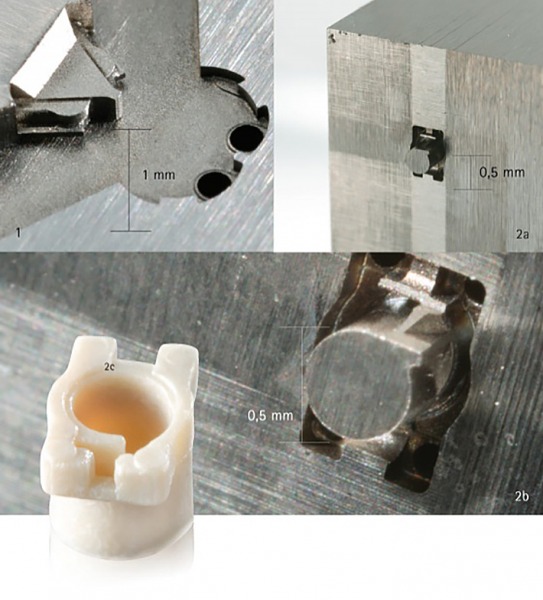

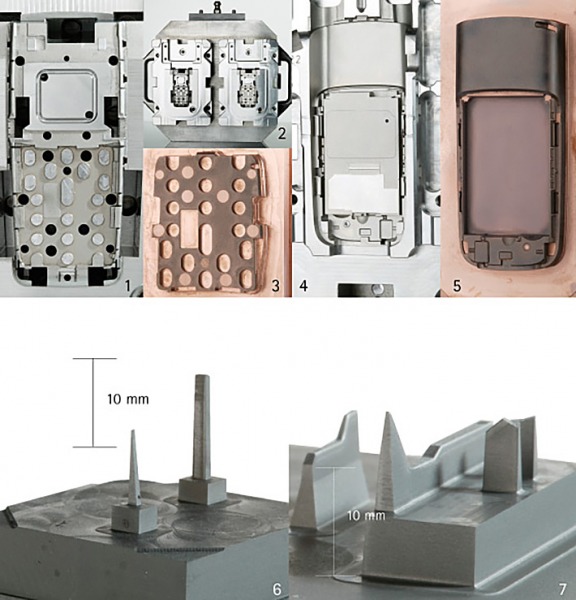

1) Slide mould fibre optic technology

2a) 0.5 mm work piece

2b) Enlargement of the work piece

2c) Finished moulded part, final size 2 x 1.5 mm