Do you have questions about our products?

Do you need our service?

Contact

Michael Huth

+49 - 6161 - 93 07 - 44

moc.m1769137683etsys1769137683-kz@h1769137683tuh.m1769137683

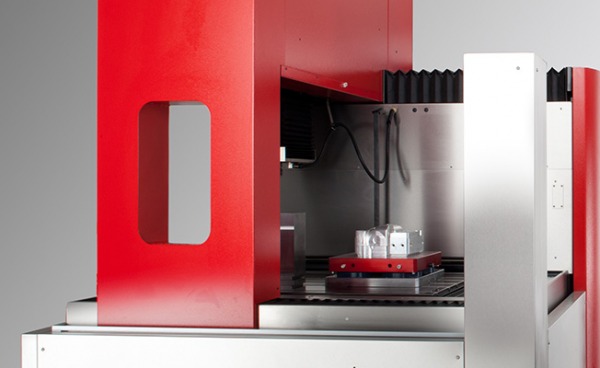

How do you machine tall work pieces? The best way is with our genius 1000. It combines highest stability with rigidity through the construction in the mineral cast bed. As a modified half gantry with two synchronised digital drives in the x-axis, it provides an intelligent, control solution. It thus offers interesting proportions, which are designed specifically for machining tall work pieces – and with exemplary machine precision.

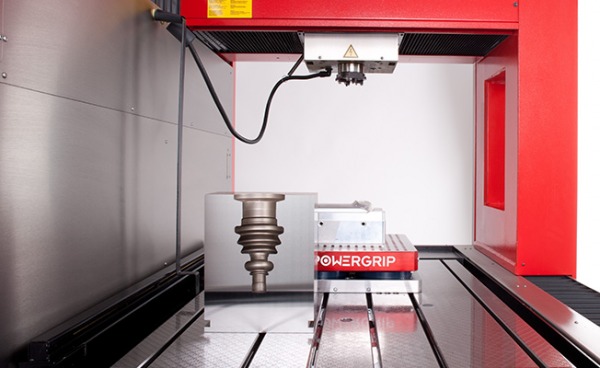

All linear axes are equipped with glass scales. This way they achieve particular fineness even with large work pieces. With a dielectric fluid height of 500 mm above the table, it offers an exceptional processing height, thus covering a wide size range of electrodes and work pieces.

The travel range of the machine is also suitable for very large work pieces. The intelligent control system allows you to synchronously control 6 axes as EDM axes. This is a real advantage if you have to deal with complex geometries or free forms. At the same time, the machine allows for the organisation of more efficient processes with large quantities.

Despite its size, the genius 1000 can be set up in surprisingly small spaces. Its compact design makes it easily accessible and loading with a crane very simple. The connection to automation is possible from three sides, so that you can place this machine wherever you need it in your company. The height-adjustable control desk ensures ergonomic working for everybody regardless of height. Due to the great accessibility of the service unit, it is particularly easy to maintain and service, saving you even more time.

| Travel distance X – Y | 700 x 500 mm |

|---|---|

| Travel distance Z | 500 mm |

| Table: Length x width | 900 x 700 mm |

| Distance: Table – sleeve w / o chuck max. / min. | 650 / 150 mm |

| Dielectric fluid above table | 500 mm |

| Overall dimensions (w x d x h) | (1,650 x 3,064 x 3,050 / 1,825) mm |

| Total weight (w / o fluids) | 6500 kg |

| Workpiece weight | 1500 kg |

| Electrode weight w /o rot. head | 100 kg |

| Electrode weight w. rot. head | 50 kg with man. safety |

| Rapid traverse speed X – Y | 10 m / min |

| Rapid traverse speed Z | 18 m / min |

| Resolution X – Y – Z | 0.001 mm |

| Resolution C | 0.001° |

| Dielectric fluid consumption | 700 litres |

| Generator | genius magic3 |

| Operating current | 80 A (+ 80 A with booster) |

| Suction capacity | 200 m3 / h (55 l / sec) |

| Required cooling capacity | 2.5 kW |

| Floor load | 3.5 N / mm2 |

| Number of adjustable feet | 3 |

| Weight per foot | 2 t |

| Diameter of base plate | ø 110 mm |

| Flow rate (air) | 10 l / min |

| Required air pressure | min. 6 bar |

| T-slots: number / width / distance | 6 slots / 12 mm / 150 mm, 3 x 100 mm, 150 mm |

| Pleated paper filter | 2 pcs. |

| Flushing device | 1 Pressure port 1 Suction connection 1 Fine amount pressure port |

| Flush flow regulator | continuously variable |

| PROGmodEDM | Programming software |

| Electrode changer | 24-fold |

|---|---|

| Change system Multi-Change | Robot system Chameleon: All-in-one solution for all pallet and electrode combinations |

| Sleeve system, pallet system | EROWA, 3R, Hirschmann, POWERGRIP, Mecatool etc. |

| C-module | for carbide metal working |

| O-module | for very fine surfaces |

| Flushing device | expandable to 12 connections |

| JOBmodEDM | order control system |

| IDENTmod | Identification |

| Swing / rotary table | 5th + 6th simult. EDM axis |

| High pressure flushing | possible |

Machine Details

Processing height of 500 mm above the table or the chuck.