Do you have questions about our products?

Do you need our service?

Contact

Michael Huth

+49 - 6161 - 93 07 - 44

moc.m1769137347etsys1769137347-kz@h1769137347tuh.m1769137347

Are you looking for a machine that executes especially the precise, small EDM work with high long-term precision? With the genius 602, we offer a machine with the same control system as our large machines – and it shows in the precision. The difference: the genius 602 fits into every company. It is accessible from three sides, has a relatively low weight and is the most space-saving EDM machine on the market in its class. In relation to its size, it offers a maximum dielectric fluid height above the table, and the tank is integrated into the base, fully retractable and continuously variable.

The temperature of the dielectric fluid is automatically controlled via a thermostat. The rigid cast iron construction with pre-stressed anti-friction guideways avoids vibrations and thus ensures stability. Even on unstable floors, the three-point set-up ensures a continuously uniform alignment. The travel range of the genius 602 optimally utilises the size of the table, making the machine suitable for a wide range of tasks. In addition, it also allows you to take a first step towards automation.

| Travel distance X – Y | 350 x 250 mm |

|---|---|

| Travel distance Z | 315 mm |

| Table: Length x width | 576 x 400 mm |

| Distance: Table – sleeve w / o chuck max. / min. | 550 / 240 mm (optional 615 / 305 mm) |

| Dielectric fluid above table | 365 mm |

| Overall dimensions (w x d x h) | 900 x 1680 x 2540 mm |

| Total weight (w / o fluids) | 2000 kg |

| Workpiece weight | 500 kg |

| Electrode weight w. rot. head | 15 kg |

| Electrode weight w / o rot. head | 50 kg with man. safety |

| Rapid traverse speed X – Y | 2 m / min |

| Rapid traverse speed Z | 4 m / min |

| Resolution X – Y – Z | 0.001 mm |

| Resolution C | 0.001° |

| Dielectric fluid consumption | 250 litres |

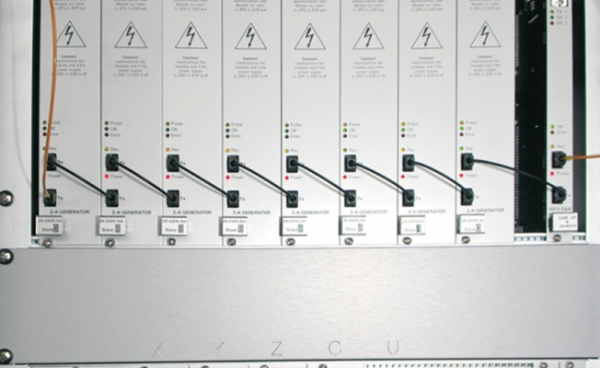

| Generator | genius magic3 |

| Operating current | 50 A |

| Suction capacity | 200 m3 / h (55 l / sec) |

| Required cooling capacity | 2.5 kW |

| Floor load | 3.5 N / mm2 |

| Number of adjustable feet | 3 |

| Weight per foot | 1 t |

| Diameter of base plate | ø 60 mm |

| Flow rate (air) | 10 l / min |

| Required air pressure | min. 6 bar |

| T-slots: number / width / distance | 4 slots / 10 mm / 3 x 100 mm |

| Paper cartridge filter | 3 pcs. |

| Flushing device | 3 Pressure ports 1 Suction connection 1 Fine amount pressure port |

| PROGmodEDM | Programming software |

| Electrode changer | 16-fold |

|---|---|

| Change system Multi-Change | Robot system Chameleon: All-in-one solution for all Pallet and electrode combinations |

| Sleeve system, pallet system | EROWA, 3R, Hirschmann, POWERGRIP, Mecatool, etc. |

| C-module | for carbide metal working |

| O-module | for very fine surfaces |

| Flush flow regulator | 15-fold |

| Flushing device | expandable to 14 connections |

| Q-axis | 5th EDM axis |

| Rotation head | up to 700 r / min |

| High pressure flushing device | possible |

| JOBmodEDM | order control system |

| IDENTmod | Identification |

| Temperature compensation | possible |

| High pressure flushing | possible |

Machine Details

Dielectric level above table: 365 mm

for maximum transmission speeds and robustness

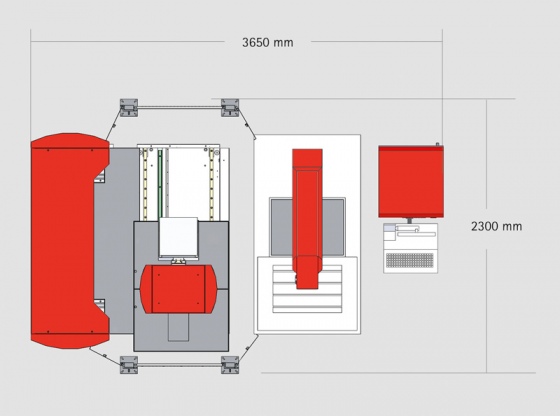

Floor space required for the smallest automated unit

The genius 602 with the Handlingsystem Chameleon forms the Smallest automated system. With dimensions of 3650 x 2300 mm, this unit is ideal for very small workshop situations.