Do you have questions about our products?

Do you need our service?

Contact

Michael Huth

+49 - 6161 - 93 07 - 44

moc.m1769142452etsys1769142452-kz@h1769142452tuh.m1769142452

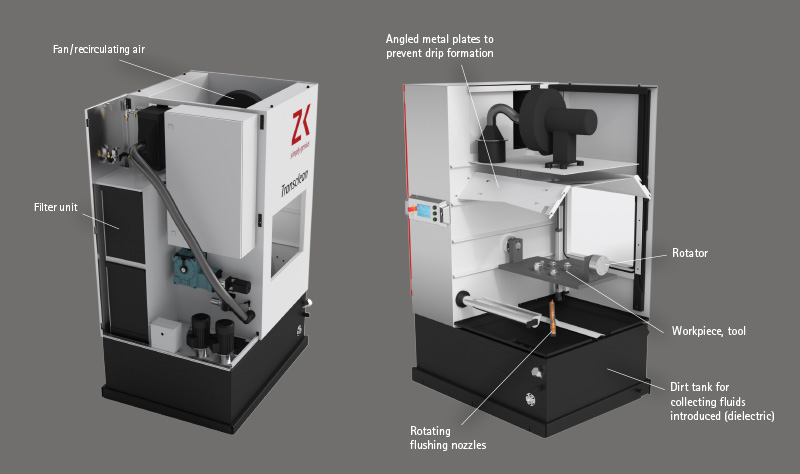

Transclean – stand-alone and automatic cleaning station for tools, workpieces and electrodes

Save costs – increase efficiency.

That is Transclean‘s greatest advantage. Because timeconsuming manual cleaning becomes a thing of the past when you use this system. Workpieces, electrodes, tools – everything is automatically cleaned while your employees follow more important process workflows. And the best thing is: By integrating the cleaning station into fully automatic operation, you are closing the last gap in your process chain. With it you also have your measuring process automatically under control.

The USPs at a glance

- Cleans workpieces, tools and electrodes

- Suitable for all clamping systems

- Stand-alone operation

- Use in all fully automated cells

- Use in mono cells, e.g. milling cell with minimum

charge lubrication or eroding cell - Can be used as transfer station

- Different washing programmes can be selected

- Washing fluid can be regenerated

- Economical energy consumption

- Plug and play – just set-up and start

| Dimensions (W x D x H) | 1,700 x 1,300 x 2,500 mm |

|---|---|

| Weight | 1,500 kg |

| Output | 6 kW / 400 Volt |

| Waste tank | 230 l |

| Chip basket | 3 l |

| Filling capacity of cleaning fluid | 200 l (max. 265 l) |

| Pallet size (max.) | 600 x 400 x 300 mm (x, y, z) |

| Pallet weight (max.) | 250 kg |

| Clamping systems | PARTOOL: PowerGrip Erowa: ITS, UPC, PowerChuck 3R: Makro, Dynafix |

The result counts

Whether fully automated or stand-alone – the Transclean provides perfect results. It starts with the commissioning process: Set-up and start – cleaning using the Transclean is child‘s play, particularly in stand-alone operation. In the fully automated process, Transclean is operated through the Chameleon handling system and controlled by the zuk software. Alongside cleaning, the Transclean also takes over the task of a transfer station. Which means there are several arguments in favour of you installing a Transclean in your plant: Improved processing times and higher quality while saving costs at the same time.

Quite simply a clean solution.

Technical specifications

Machine Details

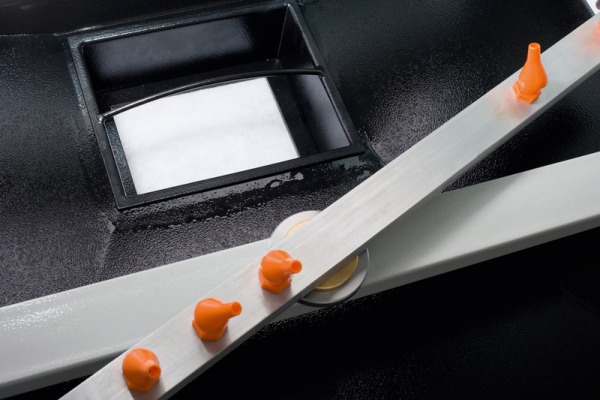

ZK-Cleanfit – This is the name of the fluid that makes sure your parts get cleaned. Its composition is specially geared to the requirements of tooling and mould building and the dirt deposits that occur there. The fluid is exclusively available through Zimmer&Kreim.

Going easy on resources:

Our engineers have thought of that, too. The special cleaning fluid develops low flash-off, which escapes when the doors are opened, however. Special safety precautions and protective measures are thus not required. The fluid can also be reused at any time. It is cleaned in the closed Transclean system, dirt particles are filtered out. The cleaned fluid is fed back into the fluid tank and used again during the next washing process. This goes easy on the environment and material requirements.