Do you have questions about our products?

Do you need our service?

Contact

Michael Huth

+49 - 6161 - 93 07 - 44

moc.m1769142215etsys1769142215-kz@h1769142215tuh.m1769142215

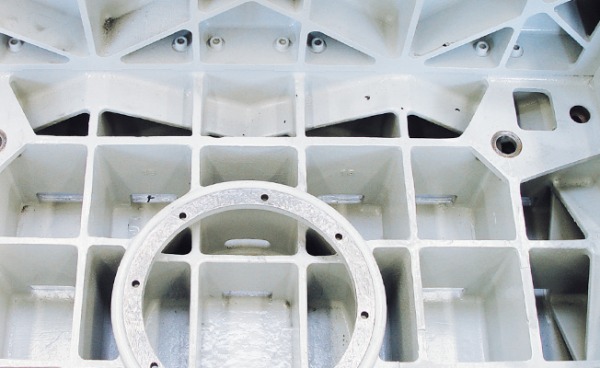

We offer clean design combined with maximum stability. The genius 1200 is designed for the real big tasks. The machine is constructed in gantry style. Even very heavy work pieces can be processed with the highest precision due to the rigid cast iron design.

Despite its size, you can set up the machine using comparatively little space, since it is easily accessible from all sides for maintenance and service work.

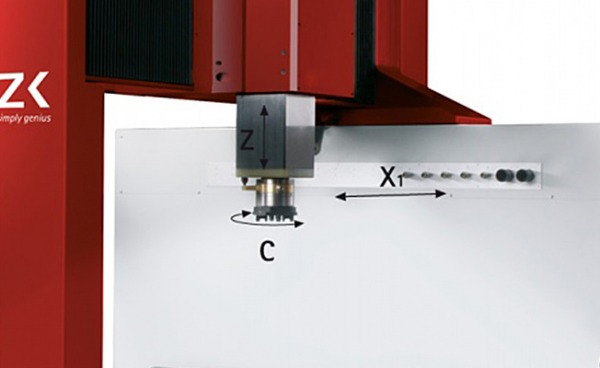

The genius 1200 is equipped with a 5-axis CNC control system and has two simultaneous drives, each with measurement systems for the gantry of the x-axis, which are directly attached. This allows you to process large electrode dimensions as well as small parts on large work pieces. The tank can be continuously lowered, saving you time. Interruptions for pumping, flooding or temperature adjustments are avoided and idle times reduced.

| Travel distance X – Y | 900 x 680 mm |

|---|---|

| Travel distance Z | 405 mm |

| Table: Length x width | 1200 x 850 mm |

| Distance: Table – sleeve w / o chuck max. / min. | 650 / 235 mm (optional 750 / 325 mm) |

| Dielectric fluid above table | 410 mm |

| Overall dimensions (w x d x h) | (1,540 x 1,520 x 2,710) mm |

| Total weight (w / o fluids) | 3700 kg |

| Workpiece weight | 3000 kg |

| Electrode weight w /o rot. head | 100 kg |

| Electrode weight w. rot. head | 50 kg with man. safety |

| Rapid traverse speed X – Y | 2 m / min |

| Rapid traverse speed Z | 4 m / min |

| Resolution X – Y – Z | 0,001 mm |

| Resolution C | 0,001° |

| Dielectric fluid consumption | 900 litres |

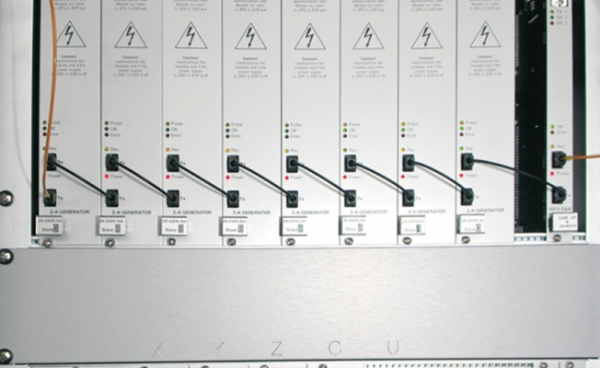

| Generator | genius magic3 |

| Operating current | 80 A (+ 80 A with booster) |

| Suction capacity | 200 m3 / h (55 l / sec) |

| Required cooling capacity | 2,5 kW |

| Floor load | 5,5 N / mm2 |

| Number of adjustable feet | 3 |

| Weight per foot | 1,5 t |

| Diameter of base plate | ø 60 mm |

| Flow rate (air) | 10 l / min |

| Required air pressure | min. 6 bar |

| T-slots: number / width / distance | 6 slots / 12 mm / 5 x 145 mm |

| Paper cartridge filter | 6 pcs. |

| Flushing device | 3 Pressure ports 1 Suction connection 1 Fine amount pressure port |

| PROGmodEDM | Programming software |

| Electrode changer | 16-, 24-fold |

|---|---|

| Change system Multi-Change | Robot system Chameleon: All-in-one solution for all pallet and electrode combinations |

| Sleeve system, pallet system | EROWA, 3R, Hirschmann, POWERGRIP, Mecatool etc. |

| C-module | for carbide metal working |

| O-module | for very fine surfaces |

| Flush flow regulator | 15-fold |

| Flushing device | expandable to 14 connections |

| Circular / swivel table | 5th + 6th EDM axis |

| Rotation head | up to 700 r / min |

| High pressure flushing device | possible |

| JOBmodEDM | order control system |

| IDENTmod | Identification |

| High pressure flushing | possible |

Machine Details

for maximum transmission speeds and robustness.