Do you have questions about our products?

Do you need our service?

Contact

Michael Huth

+49 - 6161 - 93 07 - 44

moc.m1770426366etsys1770426366-kz@h1770426366tuh.m1770426366

The smallest automated system – the cavity-sinking cell.

Perfection designed for expansion.

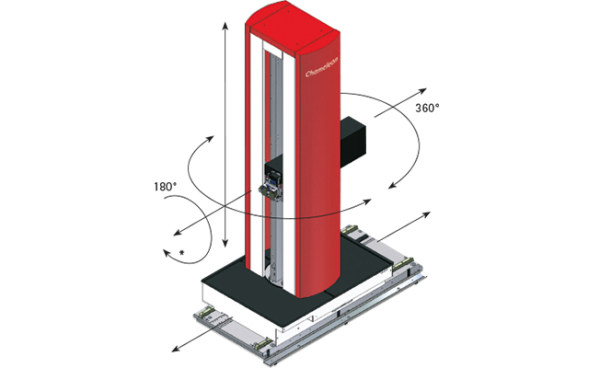

The smallest automated system combines the system spanning adaptability of the Handlingsystem Chameleon with the highly precise capabilities of our genius cavity-sinking machines. It’s up to your tasks whether the smallest automated system will grow or whether it will continue to work just perfectly inside its compact casing.

It’s phenomenal what’s inside the the smallest automated system.

- Handling-system changes both work-pieces and electrodes

- Additional connection to HSC milling-machines and other technologies possible

- Networked and independent control

- Software solution with interface connectivity

- Handling-system can be expandedstep by step at any time

- More configuration alternatives available

| Travel distance X – Y | 350 x 250 mm |

|---|---|

| Travel distance Z | 315 mm |

| Table: Length x width | 576 x 400 mm |

| Distance: Table – sleeve w / o chuck max. / min. | 550 / 240 mm (optional 615 / 305 mm) |

| Dielectric fluid above table | 365 mm |

| Overall dimensions (w x d x h), (with Chameleon) | 900 x 1680 x 2540 mm (3450 x 2300 x 2540 mm) |

| Total weight (w / o fluids), (with Chameleon) | 2000 kg (2880 kg) |

| Electrode weight w. rot. head | 50 kg with man. safety |

| Workpiece weight | 500 kg |

| Electrode weight w / o rot. head | 50 kg |

| Rapid traverse speed X – Y | 2 m / min |

| Rapid traverse speed Z | 4 m / min |

| Resolution X – Y – Z | 0,001 mm |

| Resolution C | 0,001° |

| Dielectric fluid consumption | 250 litres |

| Generator | genius magic3 |

| Operating current | 50 A |

| Suction capacity | 200 m3 / h (55 l / sec) |

| Required cooling capacity | 2,5 kW |

| Floor load | 3,5 N / mm2 |

| Number of adjustable feet | 3 |

| Weight per foot | 1 t |

| Diameter of base plate | ø 60 mm |

| Flow rate (air) | 10 l / min |

| Required air pressure | min. 6 bar |

| T-slots: number / width / distance | 4 slots / 10 mm / 3 x 100 mm |

| Paper cartridge filter | 3 pcs. |

| Flushing device | 3 Pressure ports 1 Suction connection 1 Fine amount pressure port |

| PROGmodEDM | Programming software |

| Electrode changer | 16-fold |

|---|---|

| Change system Multi-Change | Robot system Chameleon: All-in-one solution for all Pallet and electrode combinations |

| Sleeve system, pallet system | EROWA, 3R, Hirschmann, POWERGRIP, Mecatool, etc. |

| C-module | for carbide metal working |

| O-module | for very fine surfaces |

| Flush flow regulator | 15-fold |

| Flushing device | expandable to 14 connections |

| Q-axis | 5th EDM axis |

| Rotation head | up to 700 r / min |

| High pressure flushing device | possible |

| JOBmodEDM | order control system |

| IDENTmod | Identification |

| Temperature compensation | possible |

| High pressure flushing | possible |

Machine Details

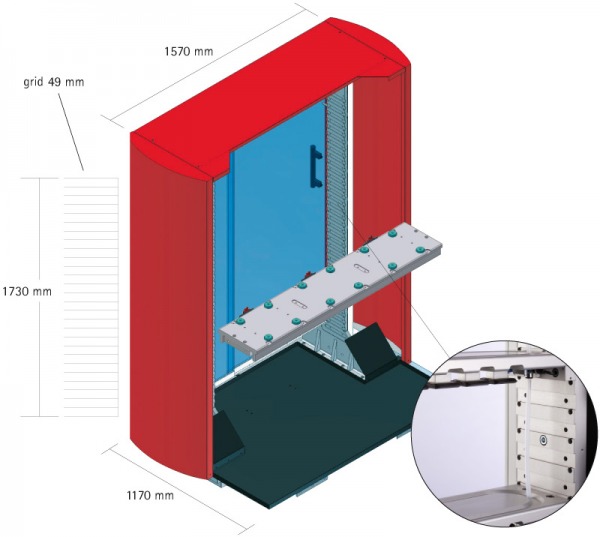

Dielectric level above table: 365 mm

The magazine shelves can be optionally equipped with LED lights. These provide an overview of ongoing processes from a distance, e.g. red for occupied and green for available. The assignment of up to 7 colours is freely programmable, and can be set up to your own sorting criteria.